1. Installation context

MM spa, a utility operator in the Province of Milan, undertook a project to upgrade the municipal water filtration section at the Milan San Rocco plant. MM’s stakeholder, an experienced plant engineer, needed an efficient solution to improve the treatment of purified water following a secondary settling process.

The main challenge involved increasing the filtration capacity, in parallel with the existing sand filters, to handle a variable flow rate ranging from 0.5 m³/s (1,800 m³/h) to a maximum of 2.6 m³/s (9,360 m³/h). In addition, the client required that the filters be able to effectively reduce the concentration of total suspended solids (TSS), which ranged from as low as 20 mg/l to as high as 50 mg/l at the inlet.

2. Proposed solution

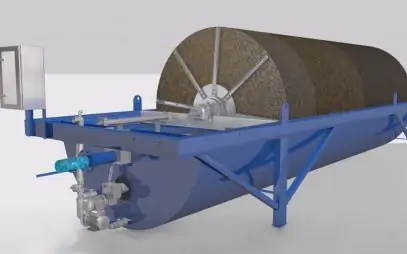

MITA Water Technologies was selected to supply 6 MSF 32/160 PPC HD model pile cloth filters. These filters were chosen for their advanced technical features, including their construction of AISI 316 L stainless steel, a corrosion-resistant material ideal for water treatment applications. Each filter has 32 discs with a total filtering surface area of 160 m². The HD (Heavy Duty) version of the filters is equipped with enhanced motorization and increased transmission kinematics to ensure long-lasting, high-performance operation, even under heavy load conditions.

The filter installation was designed to operate in parallel with the existing sand filters, optimizing the filtration process and ensuring an SST output of less than 10 mg/l, with full compliance for all samples analyzed. The solution also included the supply of covers, electrical panels, and accessories required for mounting the filters inside concrete tanks.

3. Results and key success factors

The results obtained with the installation of MITA Water Technologies’ pile cloth filters have been highly satisfactory. Thanks to its ability to adapt to variable flow rates and the robustness of the installed technology, the plant can now handle a nominal flow rate of 7,920 m³/h and a maximum of 9,360 m³/h without compromising process efficiency.

The success of the project can be attributed mainly to the speed of execution and the quality of the solution proposed by MITA Water Technologies. The experience of the supplier and the proven reliability of the MSF 32/160 PPC HD filters played a key role in the success of the intervention, ensuring full customer satisfaction. The service provided, which included supervision at installation, start-up and testing, further consolidated the result of MITA Water Technologies’ supply for MM spa.

Ask for Information