1. Installation context

In 2019, a renowned yarn manufacturer based in the province of Varese contacted MITA Water Technologies for an industrial filtration solution. The company, with more than 100 years of experience in the textile industry and proud of its made-in-Italy brand, specializes in the production of high-quality yarns for sewing and knitting, while also developing products for the fashion and furniture industries.

The company needed to manage the treatment of wastewater generated by the mechanical manufacturing process. This was a particularly complex application, given the high content of total suspended solids (TSS) in the effluent, which required an efficient solution in tight spaces and with no additional civil works to be provided.

2. Proposed solution

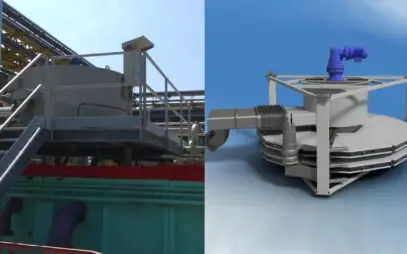

MITA Water Technologies proposed the installation of a drum filter model TF 4 VM, equipped with a filtering surface area of 4 m² and installed in an AISI 304 stainless steel metal tank. This filter was chosen for its high performance in removing suspended solids, with the ability to reduce TSS levels from 70 mg/l to less than 10 mg/l, thus meeting the company’s stringent treatment requirements.

The textile company’s sewage treatment plant was already equipped with a lamellar pack system for sedimentation and biological treatment with activated sludge. The TF 4 VM drum filter integrated seamlessly downstream of this supply chain, representing the last stage of filtration before the treated water is reintroduced or reused. Thanks to the compact design of the filter and its installation in a metal tank, no civil works were necessary-a crucial advantage for the company.

3. Results and critical success factors

The installation fully met the customer’s expectations. Thanks to the TF 4 VM filter, total suspended solids levels were reduced to below 10 mg/l, thus ensuring compliance with business requirements and environmental regulations. The average treated flow rate was 15 m³/h, ensuring efficient handling of industrial effluent with high solids content.

The critical success factor of this supply was the efficiency of the system in terms of treatment capacity and its compactness, which allowed the company to treat wastewater at the final stage while optimizing the use of production space and without additional structural interventions. The solution provided by MITA Water Technologies proved to be high performance and in line with the customer’s expectations.

Ask for Information