Sectors and Wastewater Treatment

Il tuo ambito, il tuo impianto, le tue necessità di progetto

From the high loads of the food and metallurgical industries to the final filtration in microplastics and the well-defined purification stages of civil plants: for all these sectors, MITA Water Technologies offers efficient, easy-to-install, low acquisition and maintenance cost wastewater treatment systems.

Water Treatment for municipal water

MITA's support for civil sewage treatment plants

In this area, contractors and engineering firms contacted by municipalities face a number of challenges: knowledge of regulations, managing costs, and selecting cost-effective solutions. MITA Water Technologies can support them with its efficient and easy-to-manage solutions.

Read more

Water Treatment for Food Industry

Large amounts of total suspended solids, presence of grease, extreme load variability-these are characteristics that are often found when dealing with water treatment for the food industry. Flexible systems are therefore needed, possibly with an integration of biological and mechanical treatments. However, each project must start with a rigorous test with pilot units.

Read moreWater Treatment for Plastics Industry

Total suspended solids contained in wastewater from the plastics industry are effectively removed by different MITA solutions such as decanters, floaters, sand filters or on free-fiber cloth.

Read more

Water Treatment for Paper Mills

Paper industries use a significant amount of water, with often high values in terms of total suspended solids, BOD and COD. Some of the proposed solutions: decanters, de-oilers, oxidation systems. And for finishing, some very high-efficiency filtration solutions.

Read moreWater Treatment for the Pharmaceutical Industry

BOD and COD reduction, elimination of active pollutants, very clean water to feed production processes-all needs of the pharmaceutical industry that MITA Water Technologies can address, including supporting other water treatment systems.

Read more

Water Treatment for the Chemical Industry

Toxicity and significant organic components often characterize chemical industry wastewater. Some of MITA Water Technologies' solutions facilitate the removal of pollutants, especially downstream of physical-chemical treatments: Biorulli® biodiscs, lamella-pack decanters, and free-fiber cloth filters.

Read moreWater Treatment for the Textile and Tanning Industry

Wastewater from the textile and tanning industry is rich in organics and surfactants and suspended solids (such as synthetic fibers or even heavy metals). Therefore, biological and pollutant separation treatments by flotation, often in combination, are useful.

Read more

Water Treatment for Oil & Gas

Industrial wastewater from oil & gas is very often rich in oils, phenols, polyphenols and hydrocarbons and therefore needs de-oiling, even upstream of subsequent biological treatment: lamellar pack de-oilers and flotation units are some solutions proposed for the purpose by MITA Water Technologies.

Read moreOur Range of Products

Biorulli® Biological Oxidation System

for biological wastewater treatmentAn efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as "biological disc rotors," has very low operating and maintenance costs.

Biocombi Compact Plants

For wastewater treatment of small communitiesHighly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

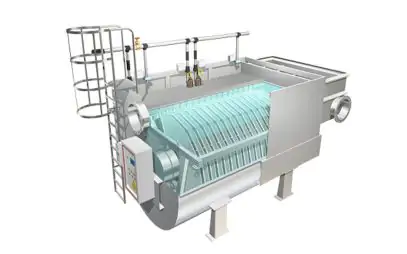

Pile Cloth Filters

for tertiary wastewater treatmentVery high suspended solid removal rates and minimal product life cycle cost: these are the advantages of pile cloth media filters for tertiary filtration. These are filtration systems suitable for industrial and civil wastewater and, in some cases, stormwater.

Filtrasand Continuous Sand Filters

for tertiary water treatmentEfficiency and continuity of operation: continuous sand filters represent a classic solution that is easy to construct and operate for wastewater finishing. Thanks to a unique patented washing system, the MITA solution allows the filter medium, i.e., sand, to be separated from impurities.

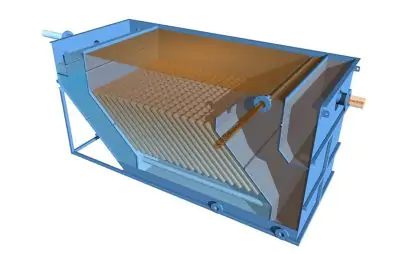

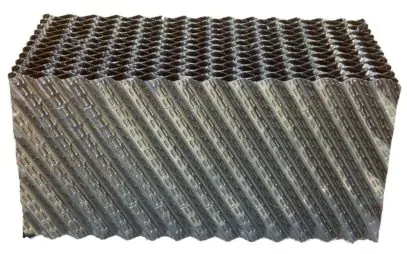

Flowpack Lamella-Pack Decanters

for sludge settlingA simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Oilpack Lamella-Pack Oil Separators

for process oil removalLamella-pack oil separators, often installed already at the primary treatment level, prevent particularly environmentally harmful components such as oils and hydrocarbons from reaching water bodies at the time of spillage. Slats inclined at 45° make the system efficient. Separated substances can also be recovered for better cost-effectiveness of the whole system.

Dissolved Air Flotation Units

for water clarificationDissolved air flotation units are devices used in water treatment processes to separate suspended solids and other particles by forming bubbles that attack solid particles to make them less dense and rise to the surface as sludge or foam. They are used in primary civil wastewater treatments and in industries such as paper, food and oil & gas. MITA Water Technologies offers Mitadaf, a highly efficient system that combines uniform hydrodynamics and microbubble filtration.

Filling Materials

for biological treatmentsWastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.

Wastewater treatment applications: some examples

Let’s start with a premise: while civil wastewater treatment plants (WWTPs) have recurring stages regulated by national and European laws (pre-treatment, primary treatment, secondary treatment, tertiary treatment), the same cannot be said for industrial wastewater.

Thus, there is no “standard” treatment process for all industrial processes or even for the same sector: it will therefore happen that, for example, a dairy or a metallurgical plant will have process water with characteristics of suspended solids and organic pollutants that are profoundly different from those of another plant in the same category. Consequently, the solution(s) to be adopted will also be heterogeneous.

This is why MITA Water Technologies always recommends a detailed analysis of the different effluents starting with pilot tests: following such a study, the best solutions of mechanical treatment, biological treatment, and so on can be selected.

Sectors and applications of wastewater treatment systems: examples

Wastewater treatment systems serve a variety of industries, each with unique needs and demands. Here are some examples.

- Food Industry. Removal of high amounts of suspended solids, fats and oils, treatment of water with high concentrations of organic matter.

- Chemical Industry. Treatment of water contaminated with hazardous chemicals, including treatment of organic and inorganic contaminants.

- Textile Industry. Removal of dyes, chemicals and suspended solids in wastewater from textile processes.

- Pharmaceutical Industry. Treatment of wastewater containing pharmaceutical substances, with stringent requirements for disinfection and removal of contaminants.

- Agriculture. Treatment of agricultural wastewater to remove pesticides, fertilizers and sediment, and for reuse in irrigation.

- Paper Industry. Removal of inks, dyes and suspended solids found in wastewater from papermaking processes.

These are just some of the sectors served by wastewater treatment systems. It should be remembered, however, that each sector, and indeed each individual plant, has specific needs based on its own processes. Therefore, a customized design of the systems, after conducting analysis with pilot test units, is a good idea.

Ask for informationsWhat is your process goal?

Tools to help you choose

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.