Civil Wastewater Treatment Stages

Our contribution to civil WWTPs

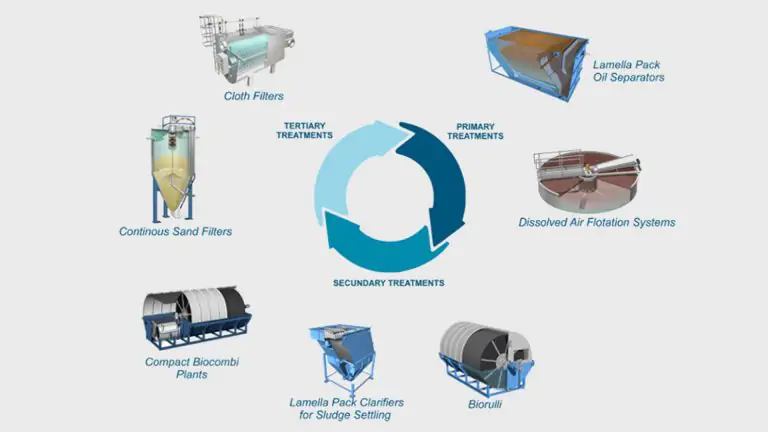

Primary, secondary, tertiary treatment: these are stages present in sequence in every civil sewage treatment plant. MITA Water Technologies offers technically simple and easy-to-install solutions for all these stages of purification, for example: biological oxidation systems, free-fiber cloth filtration, compact multi-stage treatment plants for small communities.

Primary Treatments of Wastewater

This is why "upstream" technologies must be reliable

This is the first stage of civil water purification: primary treatments (such as desanding, de-oiling, settling) are responsible for removing the "coarse" component of the effluent. Simplicity and reliability are the advantages required by these solutions, especially considering that the quality of the treated water will affect the operation of downstream technologies.

Read more

Secondary Wastewater Treatment

Water purification, "managed" by microorganisms

COD, BOD, nitrogen and phosphorus undergo a net removal process through secondary treatments. Aerobic and anaerobic bacteria are the active player in this biodegradation, which returns an effluent ready for finishing tertiary systems. Biodiscs and other compact plants show great ease of operation at this stage.

Read moreTertiary Treatment of Wastewater

The extra gear in suspended solids removal

A fining process, which refines the removal of nutrients in the effluent: tertiary wastewater treatments are particularly important processes, as they really ensure the user meets stringent regulations in terms of spills into water bodies. Many technologies in the field, including deep filtration of wastewater: high treatment yields, low resource utilization.

Read more

Our Range of Products

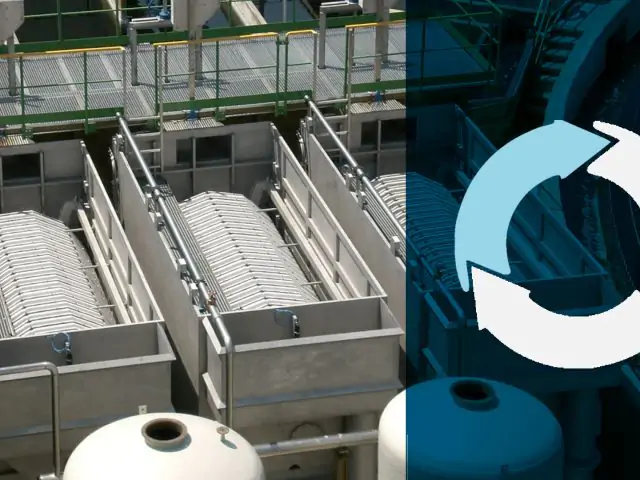

Biorulli® Biological Oxidation System

for biological wastewater treatmentAn efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as "biological disc rotors," has very low operating and maintenance costs.

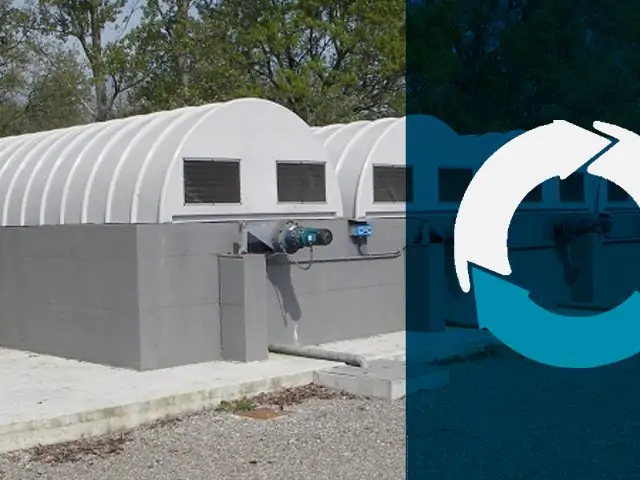

Biocombi Compact Plants

For wastewater treatment of small communitiesHighly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

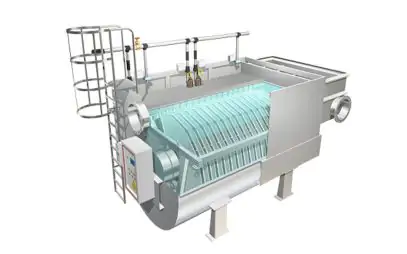

Pile Cloth Filters

for tertiary wastewater treatmentVery high suspended solid removal rates and minimal product life cycle cost: these are the advantages of pile cloth media filters for tertiary filtration. These are filtration systems suitable for industrial and civil wastewater and, in some cases, stormwater.

Filtrasand Continuous Sand Filters

for tertiary water treatmentEfficiency and continuity of operation: continuous sand filters represent a classic solution that is easy to construct and operate for wastewater finishing. Thanks to a unique patented washing system, the MITA solution allows the filter medium, i.e., sand, to be separated from impurities.

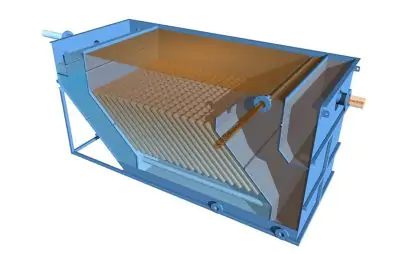

Flowpack Lamella-Pack Decanters

for sludge settlingA simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Oilpack Lamella-Pack Oil Separators

for process oil removalLamella-pack oil separators, often installed already at the primary treatment level, prevent particularly environmentally harmful components such as oils and hydrocarbons from reaching water bodies at the time of spillage. Slats inclined at 45° make the system efficient. Separated substances can also be recovered for better cost-effectiveness of the whole system.

Dissolved Air Flotation Units

for water clarificationDissolved air flotation units are devices used in water treatment processes to separate suspended solids and other particles by forming bubbles that attack solid particles to make them less dense and rise to the surface as sludge or foam. They are used in primary civil wastewater treatments and in industries such as paper, food and oil & gas. MITA Water Technologies offers Mitadaf, a highly efficient system that combines uniform hydrodynamics and microbubble filtration.

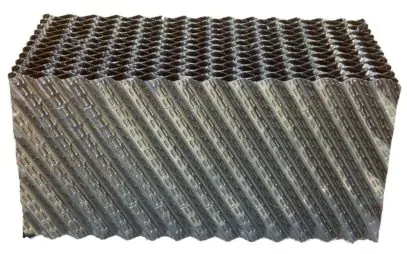

Filling Materials

for biological treatmentsWastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.

Stages of civil wastewater treatment in sewage treatment plants

In contrast to the industrial sphere, civil wastewater treatment respects a precise sequence of steps: from roughing up to reintroduction into a community’s water cycle, passing through precise mechanical and biological treatments. Indeed, one must consider that civil wastewater treatment plants serve the needs of even vast communities, ranging from hundreds to millions of population equivalents (PEs): wastewater that is very heterogeneous in terms of quantity and quality of pollutants is collected and treated.

The aim, of course, is to make the treated water safe to be returned to the environment or, in some cases, suitable for irrigation reuse.

Three phases of civil wastewater treatment can be enucleated.

- Primary Treatment. We start with a series of mechanical processes to remove the coarser solids and impurities present. Some processes: screening, sieving, desanding, de-oiling. The related technologies: mechanical screens, sand and oil separators.

- Secondary Treatment or Biological Treatment. Involves biological processes in which microorganisms (bacteria) decompose organic matter in wastewater, transforming complex organic substances into simpler, easily removed materials. Technologies used: aeration tanks, moving biological bed (MBBR) systems, biological membrane (MBR) systems, rotating biological contactors also called “biodiscs” (RBCs).

- Tertiary Treatment. This is a “finishing” stage of wastewater, which is further purified to remove residual contaminants and pathogenic bacteria. It also involves disinfection, to kill or inactivate remaining pathogenic bacteria and allow the water to be potable. Examples of technologies: sand filters, cloth filters for surface and depth filtration, reverse osmosis membranes, chlorination, UV irradiation, ozonation.

Civil wastewater treatment: technical needs

But what are the specific technical requirements of wastewater treatment? Here are them at a glance below.

- Removal of suspended solids. These are organic and inorganic solid particles of different sizes found suspended in wastewater.

- Phosphorus removal. A plant nutrient that, if present in excess, can cause water eutrophication, thus with excessive growth of algae and aquatic plants.

- Nitrogen removal. The presence of this element, if in excess, can also cause eutrophication. This can pose health hazards to animals and humans.

- BOD and COD removal. These are two measures of water quality. They stand for “Biochemical Oxygen Demand” and “Chemical Oxygen Demand”, respectively.

- Removal of oils and fats. A useful step, among other things, to prevent clogging of pipes operated by very water pollutants.

For a more in-depth discussion, you can read this page on our website.

MITA technologies for civil wastewater treatment

MITA Water Technologies provides for all stages of civil wastewater treatment some of the simplest and most effective solutions on the market: they can be integrated into any new or existing sewage treatment plant, ensuring proper disposal of the pollutant load and facilitating subsequent stages.

- Lamellar-pack decanters and de-oilers (primary treatment). They separate suspended solid particles and oils in wastewater.

- Dissolved air flotation units (DAF, primary treatment). They are used to flotate oils and fats in a roughing stage of the wastewater.

- Biorulli® biological oxidation (RBC) systems (secondary treatment or biological treatment). They act on COD, BOD and Nitrogen: disc structure of various sizes depending on the input load to be abated.

Continuous sand filters (tertiary treatment). Systems for wastewater filtration using self-cleaning sand for fine removal of suspended solids. - Free-fiber cloth filters (tertiary treatment). Systems with filter fabric with 5- or 10-micron threads, for final removal of suspended solids, with limited footprint.

- Biocombi compact systems (secondary and tertiary treatment). Combination of Biorulli and cloth filters: removal of BOD, nitrogen and removal of total suspended solids.

What is your process goal?

Tools to help you choose

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.