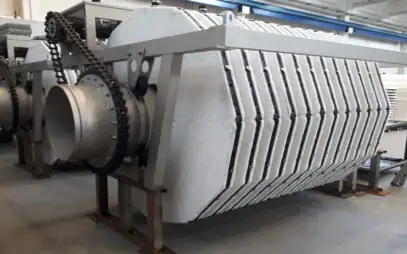

Cloth Filters and Cooling Towers for Plastic Industry

Cooling and wastewater treatment together: that's the card that proved successful in supporting a plastics equipment company in northern Italy, which was already working with MITA Cooling Technologies (now a commercial partner of MITA Water Technologies). The possibility of water reuse, through comprehensive management of this resource, is a card that industries can exploit to derive value from blue gold.

Read more