Examples of areas: Civil water treatment purifiers, small communities.

Water Treatment for municipal water

MITA's support for civil sewage treatment plantsIn this area, contractors and engineering firms contacted by municipalities face a number of challenges: knowledge of regulations, managing costs, and selecting cost-effective solutions. MITA Water Technologies can support them with its efficient and easy-to-manage solutions.

Main requirements: compliance with design specifications, reliability, and ease of operation.

Solutions for municipal utilities

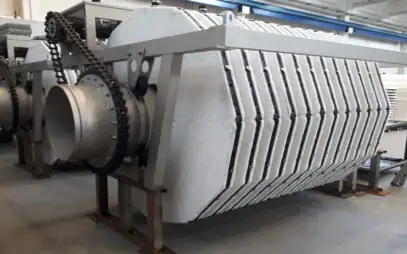

Disc Filters PEC – PEC VM

With these free-fiber filtration systems, we get to serve medium to large sewage treatment plants with minimal floor space requirements. Not only that. In the PEC and PEC VM disc filters, backwashing with sequentially driven pumps provides the machine with operational continuity in water treatment, consequently avoiding the need to provide a back-up unit.

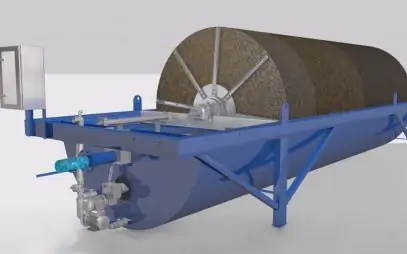

Biorulli® Biorotors B 200

The disc rollers, B 200 series, are the Biorulli® biodiscs biological oxidation solution: allowing high versatility in the face of widely varying effluent loads throughout the year. All this in conjunction with truly affordable acquisition costs.

Biocombi Monoblock BC 2

Biological oxidation and efficient depth filtration are typical features of the Biocombi Monoblock BC 2, an integrated and compact wastewater treatment system for small communities. It is a suitable solution for low water flow rates while being able to withstand significant load increases at certain times of the day and year.Civil wastewater treatment plants: processes and treatments

Let us first take a brief look at the different processes and treatments involved in each civil sewage treatment plant.

- Primary (mechanical) treatment. In this first stage, wastewater goes through sedimentation or settling to remove the heavier suspended solids. It is therefore a “roughing” stage.

- Secondary (biological) treatment. Special technologies purify the effluent of most of its organic components, taking advantage of biodegradation operated by aerobic and anaerobic bacteria. Some examples of technologies: activated sludge, mobile biological beds, biological oxidation. The product of this stage is sludge, which is more easily separated from water.

- Tertiary treatment. Further treatment to remove specific contaminants in a “finishing” stage. Cloth filtration, sand filtration, reverse osmosis, and UV radiation belong to this category.

Every civil wastewater treatment plant must include all these steps to remove contaminants: suspended solids of different sizes and types, phosphorus, nitrogen, oils and fats, BOD and COD.

Sewage treatment plants: MITA's advice to civil professionals

Contractors and engineering firms face a number of challenges when managing the design and supply of municipal water treatment systems: knowledge of national and transnational regulations, managing development and installation costs, and selecting solutions that are simple to manage. This, of course, in addition to the proper assessment of effluent quantity and quality parameters.

Water treatment technology providers are happy to relieve these professionals of responsibilities on individual sections of the project: the proposed and designed solutions must be reliable and easy to manage. Not to mention a reasonable total product life cycle cost (CAPEX and OPEX).

These are some of the technologies that, in MITA’s experience, best meet these needs of contractors and engineering firms on individual treatment stages:

- Biorulli® oxidation systems (secondary treatment). Biological treatment carried out by aerobic bacteria, which grow on the plastic biodiscs through the steps of effluent immersion and emersion and oxygenation, and degrade the organic matter in the effluent. A system as simple and convenient as it is efficient.

- Free-fiber cloth filters (tertiary treatment). Ideal solution for removal of suspended solids with outputs down to a few milligrams per liter. Cloth fibers capture suspended particles in larger quantities than a surface-only filtration. The energy used is minimal and is limited to the backwashing phase of the cloths.

- Biocombi compact systems. The synthesis of the previous two systems, in a small tank. Reduced footprint, efficiency, minimal maintenance.

Case studies for municipal utilities

Cloth Filters for the Cuma Wastewater Treatment Plant

It is one of the largest tertiary filtration systems in Europe: the MITA supply for the vast Cuma water treatment plant near Naples, having a treatment capacity of 1,200,000 population equivalents. The goal of the project was to improve the plant's purification performance.

Read moreBiocombi Compact Systems for a Wastewater Treatment Plant

MITA Water Technologies supplied the Biocombi© BC 15/2 compact plant for biological and tertiary treatment of wastewater at the Mirabello Ciria plant.

Read moreWhat is your process goal?

Tools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.