Integrated solution. Ideal for complete wastewater treatment (biological treatment and sludge separation) in small communities.

Biocombi Compact Plants

for wastewater treatment of small communities

Highly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

Minimal energy use. This is used only for the operation of the biodisc motor and for cloth backwashing.

Minimum lifecycle cost. Low acquisition, maintenance and resource utilization costs result in an excellent return on investment.

Minimal footprint. Compact solution, reduced need for ancillary works.

Flexibility with load variations. Reduced sensitivity to hydraulic and/or organic load changes.

Quick installation and start-up. Pre-assembled plants, ready to run, complete with switchboard on board the machine.

Biocombi compact wastewater treatment plants: description and operation

For wastewater treatment of small communities, downstream of pre-treatment and primary settling, integrated systems come into play to group the purification processes into a single efficient and space-saving system: these are the Biocombi compact plants proposed by MITA Water Technologies.

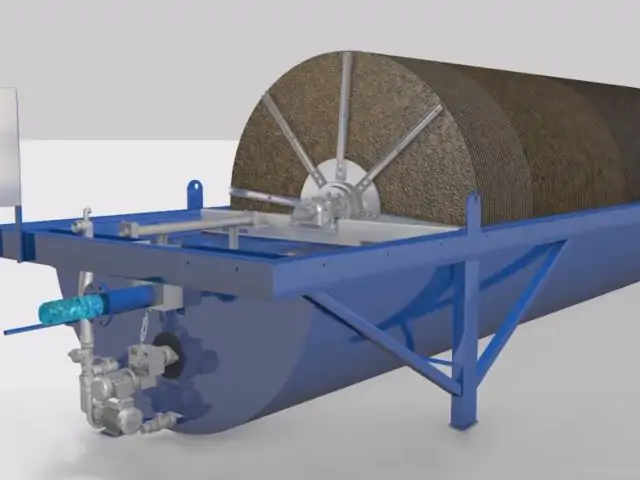

In these systems, biological treatment is carried out by means of parallel polypropylene disks, mounted on a central axis and partially submerged, on which the biomass of aerobic bacteria is formed: these feed on the colloidal and dissolved substances, according to the principle of Biorulli® biodiscs, and carry out the oxidation and biodegradation of the pollutant. In the continuation of the process, one or more drum filters accomplish the separation of the secondary sludge, more effectively replacing the secondary sedimentation basin and ensuring a high quality of the effluent even in case of variable loading (both hydraulic and in terms of suspended particles): this is due to the free-fiber cloth, equipped with countless overlapping fibers, for depth filtration.

How does the backwashing of the cloth take place? Exactly as in the case of conventional MITA cloth filters: when the surface of the drum (or two drums) becomes covered with a layer of sludge such that it causes the pressure drop to increase to a target value, a level sensor starts a pump. This, through a suction unit arranged in contact with the drum, draws in the water needed to clean the cloth itself. The sludge removed with the water is sent to the primary settling tank, if any, or to another destination.Traditional MITA cloth filters: when the surface of the drum (or two drums) becomes covered with a layer of sludge such that it causes the pressure drop to increase to a target value, a level sensor starts a pump. This, through a suction unit arranged in contact with the drum, draws in the water needed to clean the cloth itself. The sludge removed with the water is sent to the primary settling tank, if one exists, or to another destination.

The most obvious advantages of the system are:

- the minimal use of electricity,

- maintenance limited to a few simple operations (executable by unskilled personnel),

- small size,

- constant performance even under varying loads

- and last but not least, absence of noise and unpleasant fumes.

Biocombi compact systems are particularly suitable for small municipalities or hamlets, tourist resorts, hotels. Rated capacity: from 100 AE to 800 AE.

Biocombi Compact Plants: Applications

Learn about installation contexts hereDo you need info?

We wish to support you with our technologies: we are always happy to forward technical and commercial information and explanatory materials.

Ask for informationDownloads

Our range of wastewater treatment systems

Biocombi Monoblock BC 2

Biological oxidation and efficient depth filtration are typical features of the Biocombi Monoblock BC 2, an integrated and compact wastewater treatment system for small communities. It is a suitable solution for low water flow rates while being able to withstand significant load increases at certain times of the day and year.

Biocombi Monoblock BC 4

Biocombi compact plants are efficient and cost-effective solutions for wastewater treatment in small communities. These systems integrate several steps of purification into one tank, with the Monoblock BC 4 version including biodiscs for biological oxidation and two drum filters in a horizontal version for secondary sludge separation. The filtering surface area is double that of the BC 2 version: high effluent quality, even in situations of variable loads, while still having a very small footprint.

Biocombi Compact Systems for a Wastewater Treatment Plant

MITA Water Technologies supplied the Biocombi© BC 15/2 compact plant for biological and tertiary treatment of wastewater at the Mirabello Ciria plant.

Read moreWould you like a noncommittal consultation?

Tell us about your project in wastewater treatment or tertiary filtration.

Contact us nowWhat is your process goal?

Tools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.