Extreme flexibility with load variations. The system is insensitive to large variations (plus or minus) in both biological and hydraulic load, even if they last for many hours.

Biorulli® Biological Oxidation System

for biological wastewater treatment

An efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as “biological disc rotors,” has very low operating and maintenance costs.

Modularity and scalability. Facilities can be upgraded at later times by adding additional units.

Low energy use. The system works mechanically. Consequent lowering of operating costs.

Rapid, mechanical starting. The system starts up in a short time (10÷15 days) without the need for inoculation of bacterial flora.

Compactness and adaptability. The small size allows in different spatial configurations.

Ease of operation and maintenance. The purely "mechanical" operation of the machine does not require specialized personnel. The wear and tear of mechanical parts is negligible, the administration of additives or reagents is not expected.

Biorulli® oxidation system: description and operation

The Biorulli® biodisc biological oxidation system uses one or more rotating rollers to break down the organic matter contained in wastewater. It is an aerobic biological treatment system: oxygen, and the aerobic bacteria that derive “nourishment” from oxygen, play an important part in the decay of pollutants in civil or industrial wastewater.

Biodiscs are also called “biological disc rotors” or even “rotating biological contactors“.

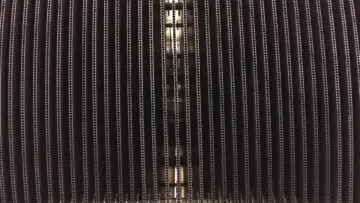

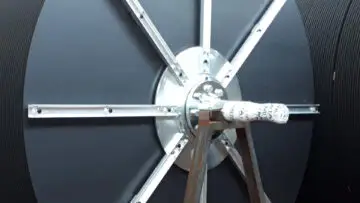

In the Biorulli® oxidation system, biodiscs are fixed on a central shaft in varying numbers depending on the model. By means of a gear motor, the shaft is turned very slowly (1 ÷ 5 revolutions per minute, depending on the model and the characteristics of the effluent). The disks, made of propylene, are partially immersed (about 40 percent of their diameter) in a tank through which the effluent to be purified flows.

It is precisely the contact between effluent and biodiscs that encourages the formation of bacterial flora on the propylene (plastic material) surface of the discs.

The flora, thanks to the continuous rotation of the discs, is alternately immersed in the sewage and brought into contact with the air: in the first phase it takes up the organic matter necessary for its nourishment, and in the second it becomes saturated with oxygen, a fundamental element of the biological oxidation process and thanks to which the bacteria themselves carry out the aerobic process. The layer of bacterial flora, having exhausted its life cycle, then independently detaches itself from the surface of the biodiscs in the form of easily sedimentable flakes.

Ask for Information

Rotating Biological Contactors: Applications

Learn about installation contexts hereDownloads

Components of Biorulli® Biodiscs

Plastic Discs

They are immersed for a little less than half (40%) of their diameter in a tank containing the sewage to be purified. They are attached to the central shaft, which is rotated. On these rollers the bacterial flora necessary for the biological oxidation process is fixed.

Central shaft

Discs of plastic material are attached to it. It is rotated by a gear motor at a speed between 1 and 5 revolutions per minute.

Basic Version

Backwash works with only one pump at a time-an additional energy saver.

Our range of Biorulli®

Biorulli® Biological Disc Rotors Monoblock M 115

Efficient, compact, extremely flexible with different pollutant loads: the Biorulli® biological oxidation system, monoblock M 115 series, is ideal for biological water treatment in apartment buildings, villas, small campsites, and factories.

Biorulli® Biological Disc Rotors Monoblock M 200

An intermediate-sized version of the one-piece biodiscs, the M 200 series is suitable for hotels, villages, small communities, and industries. Tank optionally made of treated and painted carbon or AISI 304-316 stainless steel. Efficiency and extreme ease of installation.

Biorulli® Biological Disc Rotors Monoblock M 240

It is the monobloc version, thus consisting of rollers and tank, with larger dimensions, useful for plants with more important disposal needs: nevertheless, M 240 biodiscs feature the same simplicity of installation, operation and maintenance typical of biological treatment solutions offered by MITA Water Technologies.

Biorulli® Biorotors B 200

The disc rollers, B 200 series, are the Biorulli® biodiscs biological oxidation solution: allowing high versatility in the face of widely varying effluent loads throughout the year. All this in conjunction with truly affordable acquisition costs.

Biorulli® Biorotors B 240

B 240 series biorotors are a cost-effective version for medium-sized biodiscs for biological treatment of industrial and civil wastewater to be installed in concrete tanks. Small footprint and easy and simple installation.

Biorulli® Biorotors B 290

A solution with large-diameter biodiscs for sizable plants, but with the same simplicity of installation, operation and maintenance as all Biorulli® rotating biological contactor series: these are the Model B 290 Disc Rollers.

CB 200 – CB 240 Covers

Biorulli® covers of this type can be requested by customers for biodiscs installed in concrete tanks.Some MITA Projects with Biorulli®

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Biorulli® Biodiscs

- Lamellar Pack Decanters

- Food & Beverage Industry

Biodiscs and Decanter for Italian Food Company

Integrated systems for different stages of water treatment: the key to a successful supply for a food company, through an environmentally sensitive engineering consulting firm in northern Italy.

Read more- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Biorulli® Biodiscs

- Continuous Sand Filters

- Oil & Gas

Biodiscs and Sand Filters for Coastal Depots of Esso

MITA Water Technologies provided ESSO Italiana with wastewater treatment solutions at the coastal depots in Naples and Palermo. Through the use of continuous regeneration sand filters and Biorulli(r) biodiscs, significant results were achieved, such as reduced energy consumption and maintenance costs, plant modularity, and compliance with current regulations.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read moreWould you like a noncommittal consultation?

Tell us about your project in wastewater treatment or tertiary filtration.

Contact us nowWhat is your process goal?

Tools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.