High efficiency. Biofilm media promote the growth of a layer of bacteria with high efficiency in terms of biodegradation and pollutant removal.

Filling Materials

for biological treatments

Wastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.

Minimal energy use. Natural bacterial activity is utilized for pollutant degradation activity, with much less energy input from the entire plant than other solutions.

Low clogging. These systems are designed to allow uniform water flow.

Low investment costs. Due to the extreme simplicity of installation.

Minimal maintenance. Biofilms tend to develop independently. This reduces operating costs over time.

Possibility of rehabilitation of existing facilities. In many situations, biofilm media can be added to existing facilities to improve performance without having to completely replace the infrastructure.

Our Range of Filling Materials

Bioset Biofilm Filling Materials

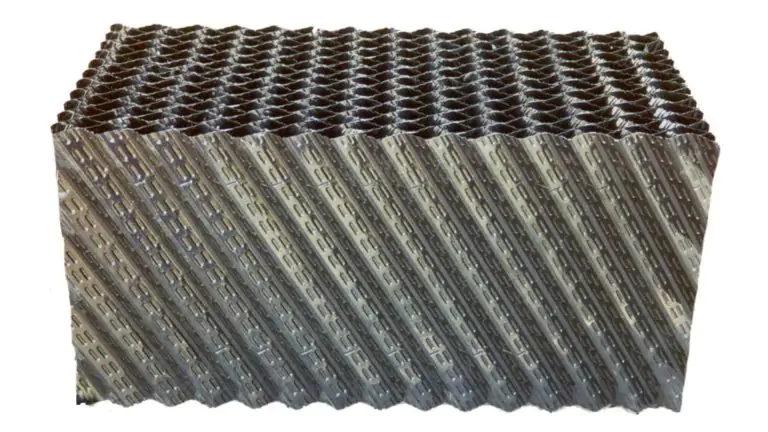

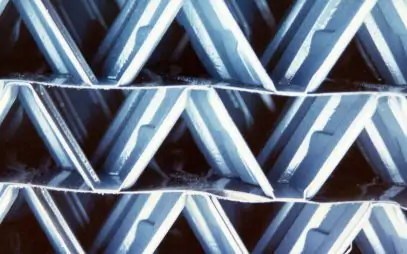

Bioset biofilm media consist of lightweight and robust PVC modules that provide a high active surface area for bacterial growth. Clear spaces between modules prevent bacterial accumulation and clogging. Percolating liquid flow is vertical or cross-current, and the slurry is lapped by naturally circulating airflow. Bioset media are easy to handle, store, and install.

Margherita Biofilm Filling Materials

Margherita biofilm filling materials are a new generation of percolator filter fills. They are made of polypropylene and have a flower shape that allows for optimal distribution within the filter. Margherita filling materials provide a high development surface area for biomass, reducing the oxygen demand of bacteria and improving wastewater treatment.Filling materials: description and operations

The major source of wastewater pollution is organic matter. Nature reacts spontaneously to this form of pollution by developing bacteria that decompose organic wastes. However, these compete with other forms of aquatic life for oxygen requirements. If oxygen is lacking, the bacteria do not survive and water quality is severely affected.

Thus, the determinant of water health is oxygen, and consequently the degree of pollution is expressed in terms of BOD, or biological oxygen demand. Percolating filters are created to meet this biological oxygen demand before the water is discharged into receiving water bodies, thus avoiding harmful eutrophication effects on rivers, lakes and seas. This also gives rise to the need for biofilm-forming filling materials, which are useful in percolating filters.

MITA Water Technologies offers two types of biofilm media.

- Margherita filling for percolator beds is the result of the evolution of fills used in the past, such as crushed stone and wood. By using this new fill material, higher structures with much higher specific surface areas and reduced risk of clogging can be achieved.

- Bioset structured filling materials consist of an alternating series of flat and/or corrugated PVC sheets, bonded together to provide a lightweight, strong and rigid structure. Such modules are therefore capable of withstanding high loads.

These structures, the result of careful design, provide high active surface area for bacterial growth in a relatively small volume and possess sufficiently large free passage spaces to avoid bacterial accumulation such as to cause clogging of the filter. Percolating liquid flow can be vertical or cross-current, depending on the design.

Ask for InformationSome MITA projects

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Oil and Grease Removal

- Biorulli® Biodiscs

- Dissolved Air Flotation Units

- Continuous Sand Filters

Water Treatment and Cooling Systems for Vedani Group

Various industrial water treatment technologies as well as cooling technologies: since 1995 MITA Water Technologies has provided multiple solutions, together with its "sister" company MITA Cooling Technologies, for the complete water management of Vedani Group, which has been active in aluminum processing since 1982.

Read moreBiological Rotors for the Chemical Company Icap-Sira

High efficiency, ease of installation, and extreme operation-these are the features that a well-known company in the chemical industry appreciated in choosing Biorulli® biodiscs for the biological oxidation of its wastewater. MITA Water Technologies has been cooperating with this industry since 2006.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read moreResources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesTools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Or You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.