High Efficiency. Due to the increased sedimentation area allowed by lamellar packs, compared to similar solutions, these devices increase the overall efficiency of wastewater treatment plants.

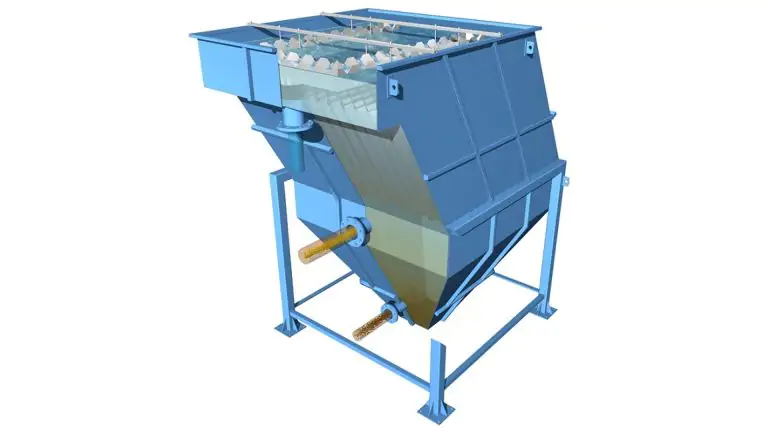

Flowpack Lamella-Pack Decanters

for sludge settling

A simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Very low pressure drop. Effect of efficient distribution of effluent through lamellar packs.

Modularity. Multiple decanters can be easily installed if the performance of the treatment plant needs to be scaled up.

Space saving. This is enabled by their compact design, which optimizes the use of water treatment facilities.

Cost-effectiveness. Lamella-pack decanters are an economical solution to improve the efficiency of wastewater treatment processes.

Ease of installation and operation. Smooth operation and low maintenance requirements simplify system operation, resulting in economic benefits.

Lamella-pack decanters: description and operation

Lamella-packs are modular elements, composed of channels of different sizes, used in different solutions to increase the useful wastewater treatment surface area. In particular, lamella-pack decanters are designed to efficiently separate suspended solids, by settling (i.e., gravity), from the water thus clarified.

It is thus a process that can also be called separation, desanding, clarification or clariflocculation (i.e., in the latter case, clarification with the addition of chemicals).

But how do Lamella-Pack Decanters work? The process can be broken down into these key steps.

- Injection of wastewater, loaded with suspended solids, in the middle of the tank. Some septa or distributors evenly distribute the flow of raw water.

- Lamella packs, with channels of different sizes depending on the consistency of the effluent to be treated, separate the suspended solids from the water.

- Sedimentation. Due to the higher density of the sludge flocs compared to water, and due to the inclination of the lamellar packs(60°), the flocs themselves rapidly decant toward the bottom of the hopper. They will then be removed, when they accumulate in defined quantities, so as not to decrease the efficiency of the process.

- The clarified water, now free of suspended solids, is at the top of the decanter and overflows into a collection channel. From here it is conveyed to subsequent treatments or, eventually, to the final discharge.

The decantation process with lamellar pack solutions is widely used, in both civil and industrial wastewater treatment, as a consequence of other biological or chemical-physical processes: speaking of civil wastewater treatment plants, it is therefore a stage of a secondary treatment. In the case of industrial installations, it is necessary to define, as always, incoming effluent quality and desired output according to local regulations: in this way, lamellar pack decanters can be evaluated as a stand-alone solution or in combination with additional technologies (both upstream and downstream).

MITA Water Technologies has decades of experience with the design, manufacture, and marketing of reed pack decanters. Several possible types of lamella packs are available, depending on the quality of the effluent. In the monobloc version, the wetted parts are made of treated and painted carbon steel, while the overflow channel is made of AISI 304. Special materials and executions are available upon request. The supply of the lamellar pack only involves insertion into a stainless steel retaining frame of appropriate thickness.

Lamella-Pack Decanters: Applications

Learn about installation contexts hereDo you need info?

We wish to support you with our technologies: we are always happy to forward technical and commercial information and explanatory materials.

Ask for InformationDownloads

Our range of decanters

Flowpack Lamellar Decanters with F Frame

They are a solution consisting of the parallel-channel lamellar pack only. F-frame Flowpack lamellar decanters are usually used for upgrading existing settlers or for housing in concrete tanks.

Flowpack Lamella Decanters Monoblock FM

Solid-liquid separation, sludge decanting, water clarification for further finishing operations-all these are represented by the FM Monoblock Series lamella decanters. Compact, efficient and space-saving solution. Simplicity of operation and very low product life cycle costs are pluses appreciated by customers in the civil and industrial fields.Case studies with lamella decanters

Lamella Clarifiers for an Industry in Tanzania

An industry that specializes in cleaning tanker trucks needs to treat the oils in the raw effluent: the three oil separators supplied by MITA Water Technologies provide effective oil removal, ensuring treated water that meets quality requirements. Also highly rated MITA's on-site support.

Read more- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Biorulli® Biodiscs

- Lamellar Pack Decanters

- Food & Beverage Industry

Biodiscs and Decanter for Italian Food Company

Integrated systems for different stages of water treatment: the key to a successful supply for a food company, through an environmentally sensitive engineering consulting firm in northern Italy.

Read moreWould you like a noncommittal consultation?

Tell us about your project in wastewater treatment or tertiary filtration.

Contact us nowWhat is your process goal?

Tools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.