1. Installation context

Water management in industrial processes can be a problem or a resource depending on the solutions adopted: industries that decide to both treat and cool water achieve the double effect of minimizing consumption and making their production more efficient.

Like a company in northern Italy, a manufacturer of plastic equipment for various sectors: already a customer of MITA Cooling Technologies (now a partner of MITA Water Technologies) with a PMS evaporative cooling tower, between 2020 and 2023 it relies on MITA Water Technologies for three successive supplies. Specifically, the company, a multinational with a presence in four European countries, requires water treatment solutions for three industrial process lines within one of its plants. The aim: to break down suspended solids in the water, pre- and post-cooling, to reuse the blue resource for industrial machinery.

2. Proposed solution

Water reuse is becoming increasingly popular among industries, which are aware of how much value can be derived from the circular economy: tertiary treatment of wastewater allows for very high quality output.

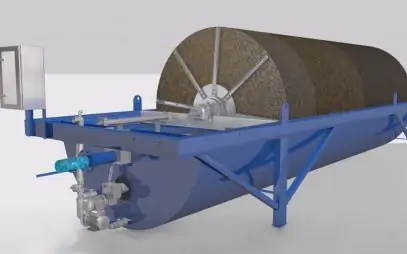

This is why MITA Water Technologies offers three different models of disc filters to the plastics customer in different tranches. First, a system with PEC 6/30 cloth filters in a concrete tank, with 6 horizontal discs, for a total filtering surface of 30 m2: a solution suitable for purification in the process line with higher average flow rate (150 m3/h). The other two lines, both with an average flow rate of about 80 m3/h, are served by a PECV VM 3/15 system (3 vertical discs, total filtering area of 15 m2); and a PEC 3/15 system in concrete tank (3 horizontal discs, also with total filtering area of 15 m2).

3. Results and key success factors

Filtration efficiency allows the removal of suspended solids in cooling water at levels below 10 mg/l-a very good quality for treated water. Phosphorus removal is a consequence of removing most of the total suspended solids.

MITA free-fiber cloth filters have greater mechanical strength than micro-net solutions, also taking advantage of the principle of depth filtration (instead of two-dimensional) and increasing the useful volume for tertiary treatment.

Also to be considered is that water filters inside the discs and the removed solids remain in the tank: therefore, the free-fiber cloth does not accumulate foreign material, improving the overall robustness of the system. Cloth washing is done by suction, reducing mechanical stress, and reducing energy consumption compared to pressure washing.

A key success factor lies, of course, in the previous supply of an evaporative tower by MITA Cooling Technologies, now a partner of MITA Water Technologies: the ability to provide integrated water cycle systems (not only treatment, but also cooling) is considered a plus by the plastics company, which then gives MITA Water Technologies the opportunity to collaborate directly in three different phases.

Ask for Information