1. Context of installation

Regulations on spillage into sewers and water bodies are increasingly stringent, in Europe and around the world. Appropriate wastewater treatment, with a good provider, ensures that companies can focus on their core processes.

Even a chemical company in the province of Monza-Brianza, Italy, in 2023 is faced with the need to treat wastewater generated by its production process. The main requirement: the removal of suspended solids, present in the discharge, so as to ensure compliance with national regulations for the discharge of wastewater into the sewer system. Inlet flow rate to be treated: 25 m3/h.

A wastewater treatment chain was already in place upstream, consisting of biological treatment, sedimenter, settler, storage tank. However, in order to reach the limits allowed by law, the installation of a filtration unit was necessary.

2. Proposed solution

MITA Water Technologies is directly proposing to the Brianza-based company the installation of a cloth filtration system. The supply consists of a single drum, model TF4 VM, with free-fiber cloth, for a filtering surface area of 4 m2.

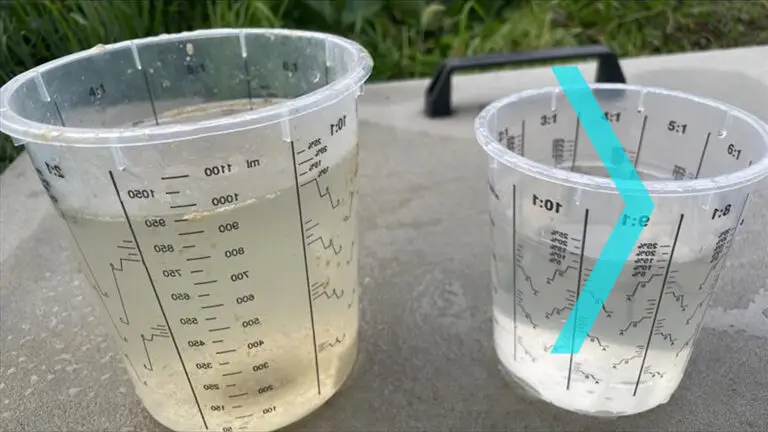

The free-fiber filters operate by passing water through the cloth, which retains suspended solids, thus allowing treated water to meet regulatory requirements. Of course, the availability of a pilot filtration unit is a prerequisite for carefully studying the specific suspended solids removal requirements prior to individual model selection, ensuring proper final design.

Assistance during installation and testing of the filtration solution are services offered to the chemical customer.

3. Results and key success factors

The implementation of the cloth filtration system leads to significant results in the treatment of the chemical company’s wastewater, with the amount of suspended solids in the outlet lower than those allowed by national regulations for discharge into the sewage system: 150 mg/l.

This efficiency is particularly appreciated by the chemical company, which can also count on the solution’s low power consumption (required only for the cloth backwashing phase). Cloth filters for tertiary treatment reppresent also an effective “barrier” for possible suffering of upstream systems.

Ask for Information