1. Installation context

A historic family-owned paper mill in northern Italy, located in Brescia, Italy, turned to MITA Water Technologies to optimize the treatment of industrial wastewater from its plant. The company has been operating for more than 40 years and specializes in the production of recycled folding cartonboard, mainly for the food industry: 50 years of history, 50 employees, an extension on more than 18,000 square meters.

In the context of a paper mill’s industrial operations, wastewater is a significant challenge. Paper processing plants generate large amounts of water containing suspended solids (as well as other nutrients): all of which must be properly treated to comply with environmental regulations.

With an average inlet flow rate of 70 m³/h and total suspended solids (TSS) concentrations ranging between 30 and 100 mg/L, the paper mill needed an efficient and reliable filtration system capable of reducing TSS to levels below 10 mg/L. This was to complement the pre-existing technologies (upstream of the new system): a dissolved air floater (DAF) and a moving bed biofilm reactor (MBBR), used for suspended solids separation and aerobic biological water treatment.

In addition, the system was to be installed in a metal tank for better management and on a small space: therefore, a flexible and compact solution was needed.

2. Proposed solution

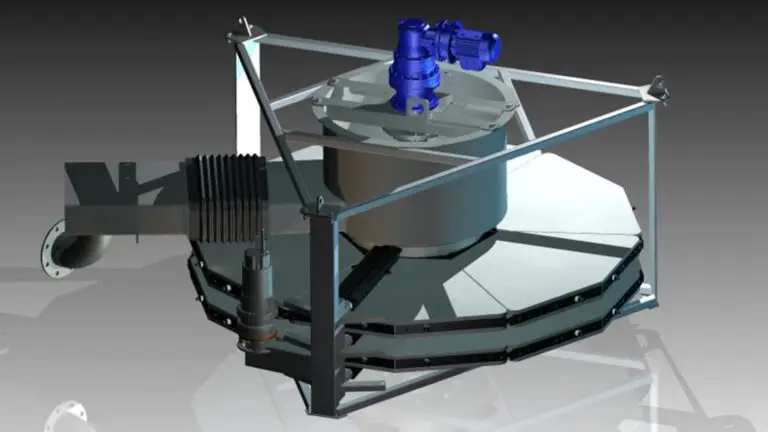

MITA Water Technologies proposed the installation of a vertical-axis filter disc system, model MSF 3/15 PECV VM, to meet the paper mill’s wastewater finishing needs. This system, with three filter discs and a total filtration area of 15 m², proved ideal for the specific context due to its compactness and filtration efficiency. The system is specifically designed together with the AISI 304 stainless steel metal tank.

The disc filters, due to their advanced configuration and technology, allow efficient removal of suspended solids. Advantages include excellent product life cycle cost, thus including acquisition (CAPEX) and operation and maintenance (OPEX). In addition, the small footprint of vertical-axis filters fits perfectly in the industrial paper mill environment where space is limited.

3. Results and critical success factors

After the installation of the filtration system, the results obtained met the expectations of the paper mill. Total suspended solids at the outlet were reduced to less than 10 mg/L, ensuring that the treated wastewater met regulatory standards. This allowed the mill to continue operations without disruptions or penalties related to wastewater pollution.

Critical success factors of the project include:

- Compactness and adaptability of the system: the installed disc filter proved ideal for the limited space available, offering high performance in a small footprint.

- Suspended solids treatment efficiency: thanks to advanced disc filter technology, the system achieved its suspended solids removal targets, significantly improving the quality of treated water.

- Operational efficiency: low energy consumption and low maintenance, typical of all pile cloth filters, help reduce overall operating costs (OPEX), improving return on investment.

Ask for Information