1. Installation context and needs

In 2016, an Italian chemical-pharmaceutical group with more than 50 years of experience in the field commissioned an industrial wastewater treatment project. The company, based in the province of Milan, is known for supplying anti-infective solutions to more than 100 countries and employs more than 3,500 people.

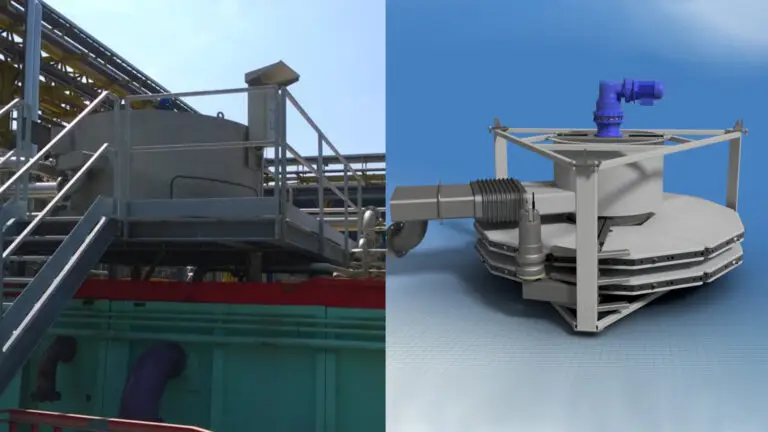

The customer’s need was to install an efficient final filtration system to remove solids from multi-department wastewater from pharmaceutical production. However, the space available for installation was very small, requiring a compact solution that could be installed on an elevated level without the need for complex civil works.

2. Proposed solution

MITA Water Technologies responded to the customer’s needs by offering a vertical-axis disc filtration system, model MSF 2/10 PECV VM. This unity consists of two filter discs with a total filtering surface area of 10 m², mounted in an AISI 304 stainless steel metal tank.

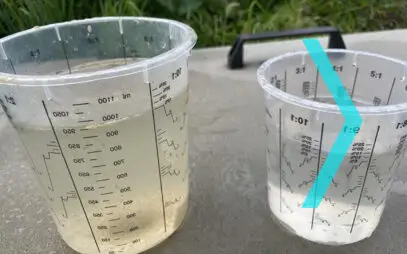

The filtration capacity of the system was sized for an average inlet flow rate of 35 m³/h with a total suspended solids concentration (TSS) of 170 mg/l. The system was designed to achieve an TSS output of less than 10 mg/l, thus ensuring effective removal of particles from the effluent.

3. Results and Critical Success Factors

The proposed solution proved ideal for the site’s limited space, allowing rapid installation without the need for complex structural modifications.

A key factor in the project’s success was the high level of efficiency in the removal of suspended solids, thanks to the pile cloth depth filtration of the technology provided. This efficiency, combined with the system’s ability to adapt to tight space conditions, was the added value for the client, who was able to benefit from a technologically advanced solution optimized for its specific needs.

Ask for Information