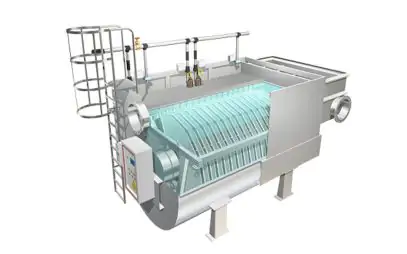

Pile Cloth Filters: Applications

They are one of the most efficient tertiary wastewater filtration solutions on the market: but what are the applications of pile cloth filters? And in what installation contexts can they be placed?

Let’s look at them below.

1. Tertiary treatment of municipal water

Pile cloth filters are used with great success for tertiary filtration of suspended solids, with an expected downstream concentration of up to < 5 mg/l: they are installed downstream of secondary settlers, in biological wastewater treatment plants for civil and industrial wastewater.

Their application stems from the need to have increasingly high water quality at the point of discharge into the receiving water body. They often represent an important barrier to the escape of light sludge, which would otherwise cause the limit on the concentration of suspended solids at the discharge to be exceeded. Crucial are simplicity of construction and operation and minimal maintenance.

2. Phosphorus reduction

Pile cloth or microfiber filters, inserted as the final stage of filtration, separate phosphorus-containing sludge as a result of the high removal of suspended solids: this is both downstream of sludge oxidation tanks and “post-precipitation” and secondary settling tanks.

3. Pre-filtration upstream of UV disinfection

Disinfection of wastewater pre-spill into water bodies is increasingly carried out with UV systems: pile cloth filters (or “free-fiber cloth filters”) reduce suspended solids to the UV-required suspended solids concentration of less than 10 mg/l, preventing fouling of the lamp surface and increasing lamp efficiency. The energy efficiency of ultraviolet systems is also preserved by installing an upstream cloth solution.

4. Filtration downstream of physical-chemical treatments

Some production processes in the industrial field lead to the production of polluted water: for example, by metals, in soluble ionic form. These can be separated in the form of sludge flocs by the dosing of appropriate chemical compounds and the use of cloth filtration: free fiber is indeed suitable for the type of chemical sludge.

Tell us your needs5. Secondary sedimentation downstream of biomass-added processes

The cloth filter is used as a substitute for secondary settling only in cases where biological treatment is carried out with biomass-adhesive type technologies: e.g., rotating biological contactors (biodiscs) and percolating beds. In these cases, the effluent from the biological stage has a sludge concentration such that it can be treated directly with a cloth filter (without a secondary settling stage): this guarantees a suspended solids content at discharge that is certainly less than 35 mg/l. It is noteworthy that MITA Water Technologies has developed a compact plant (biocombi) that combines Biorulli® biodiscs and secondary sedimentation through a cloth filter.

6. Pre-filtration upstream of membrane processes

In the case of very stringent treatment of civil or industrial wastewater, technologies with membranes of the ultrafiltration and reverse osmosis type are used: the aim is the reuse of the same water in the industrial field and sometimes also in the civil field. Reverse osmosis in particular requires effluent with very low suspended solids content in the feed to safeguard the membranes from fouling, limit flushing, and maintain system performance. Again, the cloth filter is an optimal filtration system to be inserted upstream of the reverse osmosis membranes.

7. Pre-filtration of surface water

Surface water, often used for drinking water supply, undergoes pre-filtration as its first treatment: the purpose is the separation of solid particles present in the form of silt, microalgae and the like. The pile cloth filter is a very useful filtration system.

Ask for InformationResources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.