Wastewater Reuse through Pile Cloth Media Filters

For several decades now, we have been trying to achieve a world in which clean water is no longer a depleting resource but a widely accessible commodity: it is an ambition found in the UN’s 2030 Agenda for Sustainable Development and is among the main goals of EU environmental regulations and directives, such as Directive 2000/60/EC. Now, the most conscious protagonists of this change are clear that, with more than eight billion people on the planet, proper disposal is no longer enough to ensure access to the blue resource for all: effective wastewater reuse is needed in civic communities, industry and agriculture. And even more than in other areas, the technical and functional versatility of pile cloth media filters is making its way into consultants’ and engineering firms’ designs for civil and industrial wastewater treatment plants.

In a context of increasing water scarcity and intensifying climate extremes, wastewater reuse is emerging as a strategic and sustainable solution for building a better future: will we get there, and if so, by what date?

One thing is certain: in envisioning this possible future, pile cloth filters are the perfect ally for change. Let’s look at the reasons why.

1. Perché riutilizzare le acque reflue?

Let’s start with the premise: why pursue the path of reuse of treated wastewater instead of simply disposing of the blue resource post-purification by discharge to surface water bodies?

Let’s look at some forward-looking reasons from both an environmental and (rejoice industries and agricultural enterprises) economic-productive point of view.

- Less water stress: relieving pressure on natural water resources helps to preserve aquatic ecosystems, preventing rivers and lakes from drying up and protecting biodiversity.

- Reducing freshwater consumption: by taking less water from natural sources, such as rivers and aquifers, we safeguard this valuable asset for future generations, ensuring the availability of this vital resource for domestic, agricultural and industrial uses.

- Environmental protection: by decreasing the amount of wastewater to be disposed of, pollution of waterways and seas is reduced, combating the proliferation of algae and the spread of pathogens.

- More efficient processes: this is something that is almost never considered. However, in many cases reusing industrial water from a circular economy perspective, rather than extracting new water from rivers and lakes, pursues the rationalization of what is (let’s remember) in effect a resource of production processes. Often the energy used to reuse is also less than that required to extract.

- Economic benefits: drinking water supply and treatment costs are reduced, resulting in significant savings for businesses and communities, especially in drought-prone areas.

- New opportunities: wastewater reuse creates new employment and development opportunities in innovative sectors, spurring economic growth and the creation of eco-friendly businesses.

2. Pile cloth filters: valuable allies for reuse

And now we come to the valuable ally of water reuse in municipal, industrial and agricultural settings.

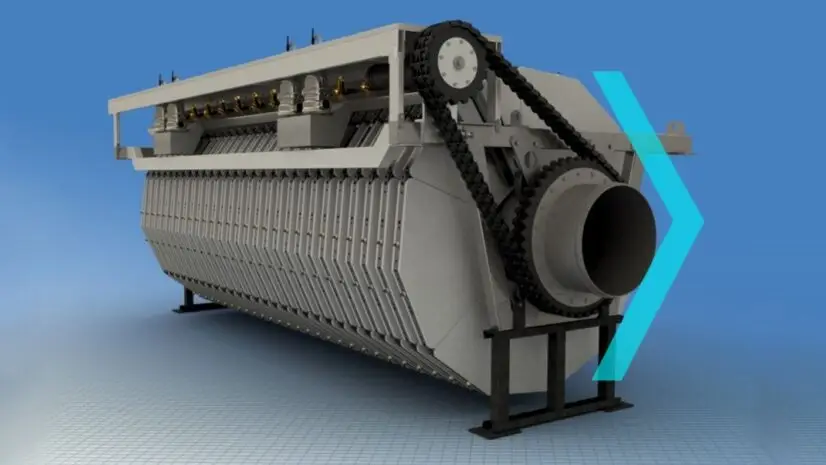

Among the various technologies available for wastewater treatment and reuse, pile cloth filters stand out for their effectiveness, versatility and sustainability. These tertiary filtration systems represent one of the final steps in the purification process: the output water thus has an excellent final quality, in terms of total suspended solids and suitable for multiple uses.

Here, then, is why pile cloth filters are the ideal choice for wastewater reuse.

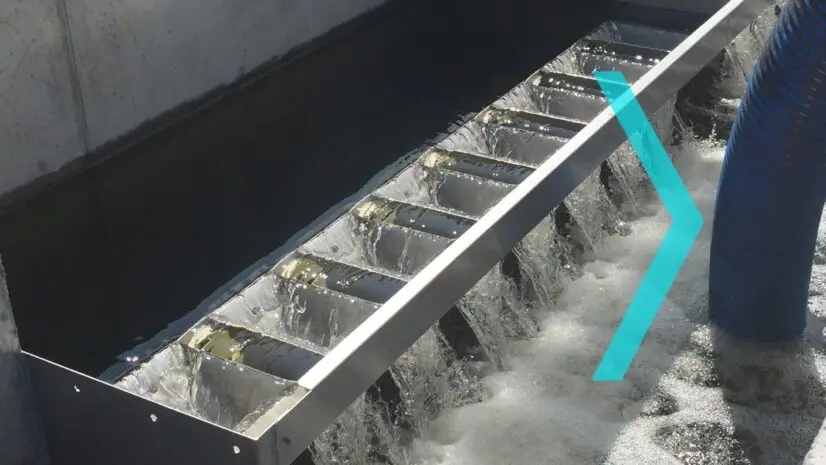

- High removal capacity of suspended solids. Thanks to their innovative design, which combines depth filtration with surface filtration, the pile cloth filters are able to guarantee a concentration of suspended solids in the treated water of less than 10 mg/l. This outstanding result results in clear, impurity-free water suitable for a wide range of applications.

- Versatility of use. Pile cloth filters can be used to treat different types of wastewater, from industrial, civil and agricultural settings. Their adaptability makes them an ideal solution for multiple reuse needs.

- Low energy consumption. The backwash system of these free-fiber cloth systems is not continuous, but is activated when needed during operation, without interrupting the physical filtration process. This optimizes operating costs and reduces environmental impact.

- Easy maintenance and low cost. Pile cloth filters require minimal maintenance, with simple and infrequent operations. This results in low operating costs and increased operational efficiency.

- Small footprint. The compact design of the tertiary filtration solution (or “final filtration”) allows for optimized installation space, making them suitable even for settings with limited available space.

These filters are thus distinguished by their versatility and effectiveness, adapting to different needs and types of wastewater:

- Industries: for reuse in production processes, plant washing, machinery cooling.

- Municipalities: for irrigating green areas, feeding ornamental fountains, washing roads. Drinking water production, on the other hand, requires additional disinfection with UV lamps or reverse osmosis solutions: however, these technologies are often preceded by fleece filters, which prevent excessive loading and fouling of downstream solutions with their effectiveness in removing total suspended solids.

- Agriculture: for watering livestock or irrigating many crops (the list is being updated by the Legislature).

3. Wastewater reuse: the regulatory framework

Wastewater reuse is not only a smart ecological choice, but also a practice regulated by a robust and evolving regulatory framework. At the European level, Directive 91/271/EEC, known as the Urban Wastewater Directive, establishes minimum requirements for the treatment of urban wastewater and regulates its reuse for irrigation purposes, provided that specific quality parameters are met.

Currently, the mother directive on the subject is Directive 2000/60/EC, also known as the Water Framework Directive. This directive establishes a general framework for water protection in Europe and promotes the reuse of treated wastewater as a means of reducing pressure on natural water resources.

In Italy, regulations on wastewater reuse were transposed and supplemented by Legislative Decree 152/2006, which defines the technical requirements for the treatment and reuse of wastewater intended for various uses, including irrigation, feeding ornamental fountains, livestock watering, and industrial use.

In addition to these general regulations, there are also specific provisions related to individual sectors, such as agriculture and industry, which define the criteria and conditions for wastewater reuse in these areas.

Importantly, the regulatory framework for wastewater reuse is constantly evolving, with the goal of promoting increasingly sustainable practices and protecting public health and the environment. Competent authorities are committed to monitoring the effectiveness of existing regulations and making necessary changes to ensure safe and responsible wastewater reuse.

Ultimately, the regulatory framework on wastewater reuse is a key pillar for promoting this virtuous practice and ensuring its sustainable and controlled development. Existing regulations, together with international guidelines and protocols, provide a solid framework to steer wastewater reuse toward an increasingly green and resilient future.

Pile cloth filters fit perfectly into the regulatory framework for wastewater reuse: this is due to their high capacity to remove suspended solids, but also because of their versatility of use, low energy consumption, and easy maintenance throughout the product life cycle.

Ask for InformationResources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.