A single interlocutor. Your partner, from design through installation to acceptance, for both individual solutions and turnkey refrigeration systems.

Refrigeration Systems for Small and Medium Enterprises

On the side of those who have to manage the entire production process

Owners and plant managers of manufacturing SMEs have a common need: to rely on simple solutions so that they can concentrate on their core processes. If the need to 'have one eye on everything in the company' is compelling, it becomes a guarantee to be able to rely on reliable refrigeration systems and a single point of contact.

Predictive maintenance. All Frigofluid systems can be monitored remotely at the customer's request.

Guaranteed performance. Regular factory testing and inspection of all solutions.

Experience throughout the process. Knowledge of the refrigeration system and its interaction with the production plant is our responsibility.

Installation support. We minimise your worries through an on-site presence during critical phases.

References in industry. We have been serving a variety of industries since 1995, thanks to the decades of experience of our founding partners.

Reliability and business continuity from industrial refrigeration

Three words small and medium-sized companies often ask of industrial refrigeration manufacturers: control, control, control.

The owners of SMEs and their direct employees often have to keep an eye on everything: the utmost focus is on business continuity, of the company and its production lines in general. The aim, of course, is always to be able to provide their customers with quality products and services on time.

For this reason, the refrigeration systems installed in the production plant must first and foremost be reliable: high-performance, energy efficient, but above all simple to operate and maintain.

Tell us your needs

Reliable, efficient and 4.0 refrigeration systems

The answer to the need for reliability and control? A single interlocutor for refrigeration, capable of

- design the main refrigeration system and auxiliary machines,

- supply complementary accessories,

- provide assistance before, during and after installation.

Not only that. The evolution of industrial equipment towards Industry 4.0 has also affected industrial chillers and coolers. This means obtaining an almost total remote control of the machinery and its correct operation within the production plant: fluid outlet temperatures, powers, operation of electrical systems can for example be verified from the company management system, at the customer’s request, without being refrigeration technicians.

Today’s cooling and refrigeration systems allow truly substantial energy optimisation: for example the RW EFC ax chiller from Frigofluid, which can also work in free-cooling mode and guarantee energy savings of up to 80% compared to systems without this functionality. The focal point, however, remains the service component during all phases of the project. And also in the future.

Solutions and services for the entire project

The refrigeration system is not just a chiller, the Frigofluid service is not just a selection.

These are the components of our product and service so you don’t have to worry about anything:

- Preliminary assessment of your need and on-site technical inspection.

- Design of customised solutions, including turnkey solutions (complete with chiller, chillers for secondary processes, auxiliary accessories and plant engineering).

- Testing and acceptance of all Frigofluid machines/plants.

- Installation assistance, start-up testing, operator training.

- Periodic F-Gas inspection, maintenance with equipped mobile workshops.

- A single interlocutor for you. At all stages of the project.

Our range of wastewater treatment systems

Biorulli® Biological Oxidation System

for biological wastewater treatmentAn efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as "biological disc rotors," has very low operating and maintenance costs.

Biocombi Compact Plants

For wastewater treatment of small communitiesHighly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

Pile Cloth Filters

for tertiary wastewater treatmentVery high solids removal yields and minimal product life cycle cost: these are the advantages of pile cloth filters for tertiary filtration. These are filtration systems suitable for industrial and civil wastewater and, in some cases, stormwater.

Filtrasand Continuous Sand Filters

for tertiary water treatmentEfficiency and continuity of operation: continuous sand filters represent a classic solution that is easy to construct and operate for wastewater finishing. Thanks to a unique patented washing system, the MITA solution allows the filter medium, i.e., sand, to be separated from impurities.

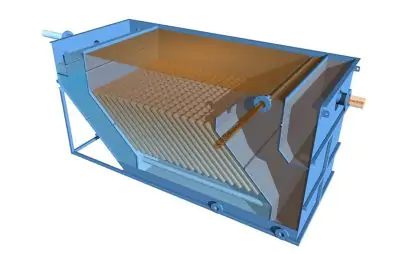

Flowpack Lamella-Pack Decanters

for sludge settlingA simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Oilpack Lamella-Pack Oil Separators

for process oil removalLamella-pack oil separators, often installed already at the primary treatment level, prevent particularly environmentally harmful components such as oils and hydrocarbons from reaching water bodies at the time of spillage. Slats inclined at 45° make the system efficient. Separated substances can also be recovered for better cost-effectiveness of the whole system.

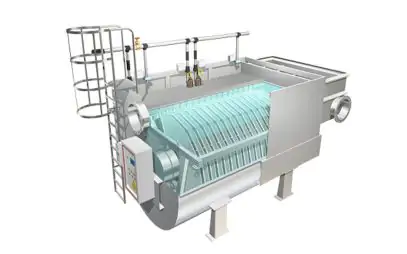

Dissolved Air Flotation Units

for water clarificationDissolved air flotation units are devices used in water treatment processes to separate suspended solids and other particles by forming bubbles that attack solid particles to make them less dense and rise to the surface as sludge or foam. They are used in primary civil wastewater treatments and in industries such as paper, food and oil & gas. MITA Water Technologies offers Mitadaf, a highly efficient system that combines uniform hydrodynamics and microbubble filtration.

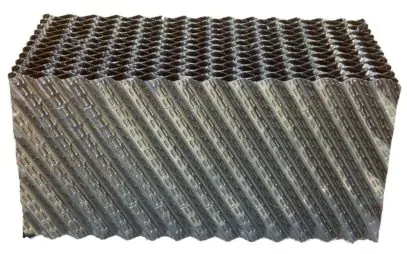

Filling Materials

for biological treatmentsWastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.

What is your process goal?

Tools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.