Regularization of effluent. The certainty of not incurring increasing environmental penalties.

Wastewater Treatment for Enterprises

Challenge... or opportunity for the company

Companies often tackle the treatment of their industrial water to avoid exorbitant fines. This is a good place to start, but it is not enough: selecting equipment with the lowest lifecycle cost, and providing the best support to the companies' consultants, turns a critical point into an opportunity for resource optimization and process rationalization.

Cancellation of discharge waivers. Discharge waivers come at a cost that can be avoided with water treatment technologies.

Ideal solutions for reuse. The reuse of treated water is an opportunity to optimize internal resources and rationalize processes.

A prepared interlocutor. Enterprise consultants and engineering firms may be relieved of part of the design of the sewage treatment plant.

Technologies at the lowest life cycle cost. Selection of equipment with affordable CAPEX (initial acquisition and installation) and OPEX (operation and maintenance) expenses.

Reliability and experience. We are part of a Group that has been involved in water management since 1960.

Why tackle industrial wastewater treatment

It is needless to deny that for many companies, process water treatment is still a major critical issue: the costs to be addressed need careful observation (especially for small companies and in times of high input prices). In addition, the space to devote to purification equipment is often very limited.

Most companies face this challenge more to normalize their effluent spills into water bodies (rivers, lakes, sea): environmental protection regulations require increasingly stringent discharge parameters (in terms of total suspended solids, BOD and COD, phosphorus, nitrogen). As a result, penalties for bad practices are increasingly exorbitant, in EU countries and other national contexts.

Tell us your needs

Industrial water treatment: the opportunity

Critical issues aside, there are at least a number of arguments for thinking of industrial water treatment as an opportunity instead of a problem: even for small businesses, even in times of “difficult” productivity.

- In case of difficulties in adhering strictly to discharge parameters, many agencies grant certain exemptions to companies: but why incur ongoing costs, rather than opting for the acquisition of appropriate systems? Many water treatment technologies have achieved very good value for money, in terms of both acquisition and installation costs and operation and maintenance: a one-time (or nearly one-time) price to avoid continuous outlays and related paperwork.

- In addition, the benefits of water reuse should be considered. This is an issue on which not only companies, but also national and supranational public bodies that can incentivize them, are increasingly sensitive: reuse is the practice of the 21st century and will be increasingly widespread in order to optimize the use of this resource (however wasteful) and the rationalization of its processes. So why treat water to throw it into a river?

MITA systems for industrial water treatment

MITA Water Technologies can give support to enterprises in the treatment and reuse of industrial water.

We can provide a range of assets to different industries.

- Technologies. We intervene in multiple stages of purification and with water of different quality, always starting from analyses with pilot units. For each type of treatment (mechanical or biological, for removing suspended solids or decreasing organic matter), we try to select the most efficient and at the same time most cost-effective solution in terms of acquisition costs and ROI.

- Consulting Engineers. For water management, companies often rely on consultants and engineering firms: we are first and foremost an ally for these professionals, contributing to the design of part of their plant and providing the most comprehensive and compliant information as required.

- Group synergies. We are part of Axius Water, an international team active in civil and process water management. To “close the loop” in supporting companies with respect to this resource so important to the economy.

Our range of wastewater treatment systems

Biorulli® Biological Oxidation System

for biological wastewater treatmentAn efficient, highly flexible, and low-energy solution for secondary treatments, the Biorulli® biological oxidation system, a solution also referred to as "biological disc rotors," has very low operating and maintenance costs.

Biocombi Compact Plants

For wastewater treatment of small communitiesHighly efficient biological oxidation and depth filtration: these two steps are integrated in Biocombi, a compact plant for wastewater treatment in small communities, i.e., small towns or hamlets, resorts, hotels. Small footprint, flexibility for sudden changes in hydraulic and/or organic load, minimal energy use.

Pile Cloth Filters

for tertiary wastewater treatmentVery high suspended solid removal rates and minimal product life cycle cost: these are the advantages of pile cloth media filters for tertiary filtration. These are filtration systems suitable for industrial and civil wastewater and, in some cases, stormwater.

Filtrasand Continuous Sand Filters

for tertiary water treatmentEfficiency and continuity of operation: continuous sand filters represent a classic solution that is easy to construct and operate for wastewater finishing. Thanks to a unique patented washing system, the MITA solution allows the filter medium, i.e., sand, to be separated from impurities.

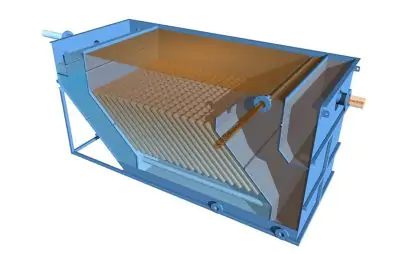

Flowpack Lamella-Pack Decanters

for sludge settlingA simple and very efficient solution: in lamella-pack decanters, solids-water separation is achieved through a dense network of channels, inclined at 60° to accelerate the settling of suspended solids.

Oilpack Lamella-Pack Oil Separators

for process oil removalLamella-pack oil separators, often installed already at the primary treatment level, prevent particularly environmentally harmful components such as oils and hydrocarbons from reaching water bodies at the time of spillage. Slats inclined at 45° make the system efficient. Separated substances can also be recovered for better cost-effectiveness of the whole system.

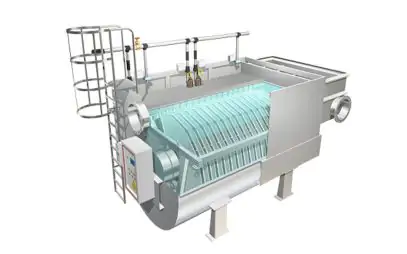

Dissolved Air Flotation Units

for water clarificationDissolved air flotation units are devices used in water treatment processes to separate suspended solids and other particles by forming bubbles that attack solid particles to make them less dense and rise to the surface as sludge or foam. They are used in primary civil wastewater treatments and in industries such as paper, food and oil & gas. MITA Water Technologies offers Mitadaf, a highly efficient system that combines uniform hydrodynamics and microbubble filtration.

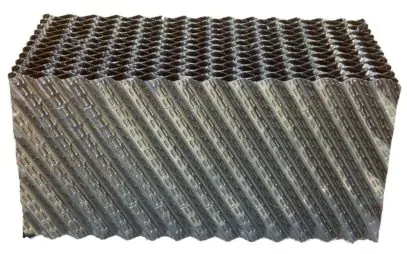

Filling Materials

for biological treatmentsWastewater is mainly contaminated with organic matter, which is decomposed by bacteria. These bacteria consume oxygen, which is essential for aquatic life. Percolating filters, and related biofilm media, provide a favorable environment for the growth of bacteria, thereby reducing oxygen demand and improving water quality.

What is your process goal?

Some MITA projects

- Industrial Wastewater

- Suspended Solid Removal

- BOD and COD Removal

- Oil and Grease Removal

- Biorulli® Biodiscs

- Dissolved Air Flotation Units

- Continuous Sand Filters

Water Treatment and Cooling Systems for Vedani Group

Various industrial water treatment technologies as well as cooling technologies: since 1995 MITA Water Technologies has provided multiple solutions, together with its "sister" company MITA Cooling Technologies, for the complete water management of Vedani Group, which has been active in aluminum processing since 1982.

Read moreBiological Rotors for the Chemical Company Icap-Sira

High efficiency, ease of installation, and extreme operation-these are the features that a well-known company in the chemical industry appreciated in choosing Biorulli® biodiscs for the biological oxidation of its wastewater. MITA Water Technologies has been cooperating with this industry since 2006.

Read moreBiorulli® Rotating Biological Contactors for ENI

Customization and long-term trust relationship: these are the two variables that decided the award to MITA Water Technologies of the revamping of the water treatment of an ENI depot in Central Italy. Rotary biological contactors, supplied to the company, are simple but efficient devices for COD removal.

Read moreTools to help you choose

Industrial and civil wastewater treatment technologies

Our support throughout the product life cycle

A sustainable and efficient solution for every industry and need

Resources

Needs of wastewater treatment

Discover the solution for all needsComparing different technologies

Find out all the different technologiesFind out more

All technical articlesOr You Can Choose

Our Newsletter

Sign up for the MITA Water Technologies newsletter: stay up-to-date on systems for municipal and industrial wastewater treatment and filtration.